What made you decide to join the Salford Racing society and how did you get involved?

Sounds cliché but I have had a lifelong passion for motorsport and cars in general, so when I saw a race car at a fresher’s fair, I was naturally drawn to it. I spoke with some of the team members who were there and they explained the project to me – how they design and build a car every year in order to compete in Formula Student, a national event where teams from the UK and overseas bring their cars to Silverstone to compete. I joined the University to study Mechanical Engineering, so the chance to do something like this alongside my studies was too tempting, I was instantly hooked!

In my first year I was responsible for the design and manufacturing of the fuel tank, as well as helping with the assembly stage. I also represented the team in the separate Formula Student Sim Racing Series, scoring 2 wins and 8 podiums, securing 2nd place in the championship! It was an amazing feeling to be representing the University on the race livestreams!

For second year, I became the Vehicle Dynamics Team Leader, managing a sub-team of 9 people overseeing the suspension geometry, steering and braking system, so not only was I applying engineering skills, but also learning leadership and management skills. I am now starting my 3rd year as the Technical Director, Operations Manager and Manufacturing Leader and cannot wait to get started!

Can you tell us what kinds of activities/ events you get involved with as part of the society?

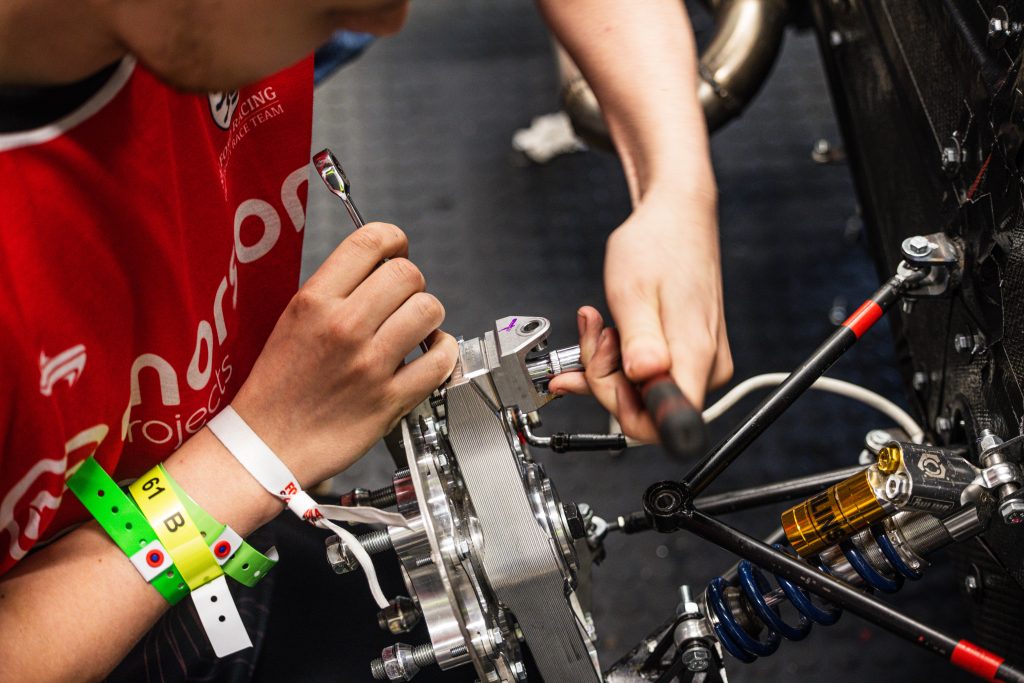

The big one would be Formula Student, that is what we work towards all year. Me trying to describe the event would not do it justice. The car we have painstakingly designed and built is judged on several criteria, such as Engineering design, Technical Inspection, as well as dynamic events including a figure of 8 skid pad, a 1km sprint lap and a 22km endurance event. Being surrounded by over 100 teams comprised of enthusiastic like-minded students, working on their own race cars at the infamous Silverstone circuit, what is not to love?!

It is not only engineering we do either, we have a dedicated business and media team who are responsible for the behind the scenes running of the team such as assessing market strategy, finances and sponsorship relations, as well as creating content for our social media channels.

We spend most of our time in the Maker Space situated in the Science, Engineering & Environment building, as it is where we do our CAD designs, rapid prototyping with 3D printers and manufacturing using professional industry standard equipment such as CNC machines, a waterjet & laser cutter and TIG welding.

We are partnered with PDC Racing who give us the opportunity to come to track days and help with testing of their own race cars, a true taste of trackside engineering. We also do a lot of outreach to local schools and colleges, including talks and workshops, to try and encourage the future generations to choose STEM subjects as career options.

‘This is a great opportunity to get stuck in, broaden your skillsets, and make new connections, whilst putting everything you learn in your studies into practice.‘

Jonathan Wheater, Mechanical Engineering Student

Have you learnt any new skills? If so, what sort of skills have you developed?

From the engineering side, being able to design components in such a way that is easy to manufacture is something which I previously did not have much experience with. For example, one design might be easy to manufacture with a 3D printer, but what if you wanted to make it out of a certain material on a 3 or 5 axis CNC Mill? What changes would have to be made, if any? Being able to spot potential issues early and tailor certain designs to a preferred manufacturing process is something you may hear about in lectures but it is an entirely different ball game when doing it for real with physical material.

Not only that but the amazing technicians in the Maker Space also provide training for all the equipment and machines, meaning you are free to use them by yourself once you have completed the training, that is something that you will not be taught on your course, here or at any other university!

From a team leader side, being able to communicate and plan effectively with others is something I did find difficult at the start. But as time went on, I became more and more confident and it became second nature to be setting up tasks for others, monitoring their progress, and steering them in the right direction when required. You also learn how to mitigate issues and find an alternative solution in a timely manner, whether that be individually or with others.

What has been your best experience with the society so far?

We were invited to the Williams F1 E-Sports lounge for the final round of the Sim Racing Championship, using high end professional sim rigs that Williams’ own E-Sports team use. The races were all livestreamed with commentary and professional videography, I was even part of the post-race interviews a couple of times! It was such a bizarre but an unforgettable experience, I did not even think something like this was a possibility when I first joined the team.

Has joining the society helped you with your studies? If so, how?

It really helps in bridging the gap between the theoretical and physical world. Having a real-world project like this available alongside studies is the perfect playground to apply lecture notes to a real problem and gain a better understanding of what we are studying.

When conducting research into specific areas of the car, it is interesting to see engineering fundamentals that we learn about in each module and how they all intertwine, especially mathematics. It can be difficult to make sense of a topic when all you have is a wall of notes and equations – being able to see a purpose for it with a physical application certainly helps when revising, as I can picture exactly why I am doing a certain order of operations and what I am trying to solve it for.

Would you recommend other students to get involved with the society. If so, why?

Without a shadow of a doubt, if you have even the most remote interest in motorsport, cars, design, manufacturing, anything like that – come speak to us! Whether that be engineering, business or media, there is something for everyone! Things like this really stand out on your CV to potential employers.

In most cases, previous alumni in job interviews were asked more about their involvement with this team than their actual degree! This is a great opportunity to get stuck in, broaden your skillsets, and make new connections, whilst putting everything you learn in your studies into practice.

well done Jonny we are proud of you our true friend

we are going to Silverstone this year yeah YEAH!!

let’s go SALFORD