How does 3D printing work? Have you heard abut 3D printing technologies? There are lots of things you could print. We have already been printed a few things already, like a duck, a Salford ambition sign and a butterfly clip!

Recent improvements and falling prices of 3D printers meant that the technology is more accessible to everyone. . 3D printing works by a layer-by-layer creation of physical objects based on digital files that of their design. Nowadays, 3D printing technologies have become an affordable and viable tool for business and consumers. So, how can 3D printing transform online retailing?

Retailers can sell blueprint design plans that consumers can purchase on the web and print at home or at 3D print shops. 3d printing has become very popular and industry in its own right since the world’s first 3D print shop opened in Zurich in 2012. Since then more pops up opened in Munich and Vienna in 2014. These shops have begun to offer bespoke final prints and designs can be adapted to improve and modify functionality. Also, electronically transmitting digital design printing have no tax costs. Nike has marketing its first athletic shoe with 3D-printed components to download and templates for shoes that can be printed out overnight. Besides industry and business, 3D scanning and printing can be used for educational purposes in schools and universities. Teachers and students can creatively combine engineering, maths, design process and history. 3D printing is also starting to revolutionise manufacturing in a wide range of industries.

However, as with our other #PUPRU emerging technologies, implementation is sometimes challenging and the problems are not just technological, but ethical, organisational and political. For some organisations who have a traditional method of work, an emerging technology may create a way of working that they never considered in their operational procedures and this may in effect force them to rethink their business models requirements and establish new policies.

There are other issues too including security, liability and intellectual property protection. This is part of the research of the #PUPRU team who are also trying to understand the effects of talking disruptive technologies into industry situations. With 3D printing we want to know how this technology could disrupt the supply chain and logistics of manufacturing industries.

What experiment #PUPRU has undertaken with 3D printing?

#PUPRU has two Formlab Form 1+ 3D Printers. Techcrunch say that it is:

“A designer’s dream machine…Full resolution and surprising detail.”

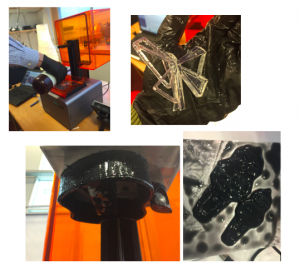

It is a complete end-to-end system allowing users to 3D print from the convenience of their desktop . It uses their PreForm software package designed to prepare any .STL or .OBJ file for printing. They are printed in a resin and as part of the process it gets coated with excess liquid resin. At the end the users remove the model from the printer build platform and then washes it in isopropyl alcohol for 20 minutes. After it is dried the models can easily be removed using cutters and the print is ready for use.

we have been doing experiments with 3D printing and made some final products, such as the butterfly clip, Apple USB case, and bookmark, duck and ambition sign shown in the picture. Our 3D digital technology was exhibited at the school Creative Entrepreneur event on 25 Nov 2015 at Media City UK where the school annual event celebrated the creative and digital economy.

So what have we learned from our 3D printing technology trials?

- The software is user friendly, easy to operate with clear instructions within the interface.

- It takes a long time to print so it would be hard to use this equipment for mass production. For example the butterfly model has 1187 layers and actually it is a relatively simple model. In medium print quality it took 3 and half hours to print and 30 minutes to finish afterwards with cutting supporting materials and cleaning the building platform.

- To speed thing up you have to use “fast print” mode where the printing time reduces by around 40% to roughly 2 hours.

- It doesn’t use too much resin, but the quality of the product is not fantastic at the faster speeds of printing.

How can you contribute to the #PUPRU 3D printing research?

We are really excited by 3D printing here in the #PUPRU team. How do you think 3D printing can help you, or have you got a business where you would like to look at how 3D printing could change the way you work? This is a fascinating project and the team want your suggestions. If you want to get involved or discuss what we are doing drop an email to our project coordinator or you can follow our Twitter feed and find out what we are interested in.